Homebrew454

Well-Known Member

Just curious where you bought this and which model you went with.Well my semi industrial walking foot machine is here. It’s an omega walking foot that does straight stitch and zig zag and has a 9” bed.

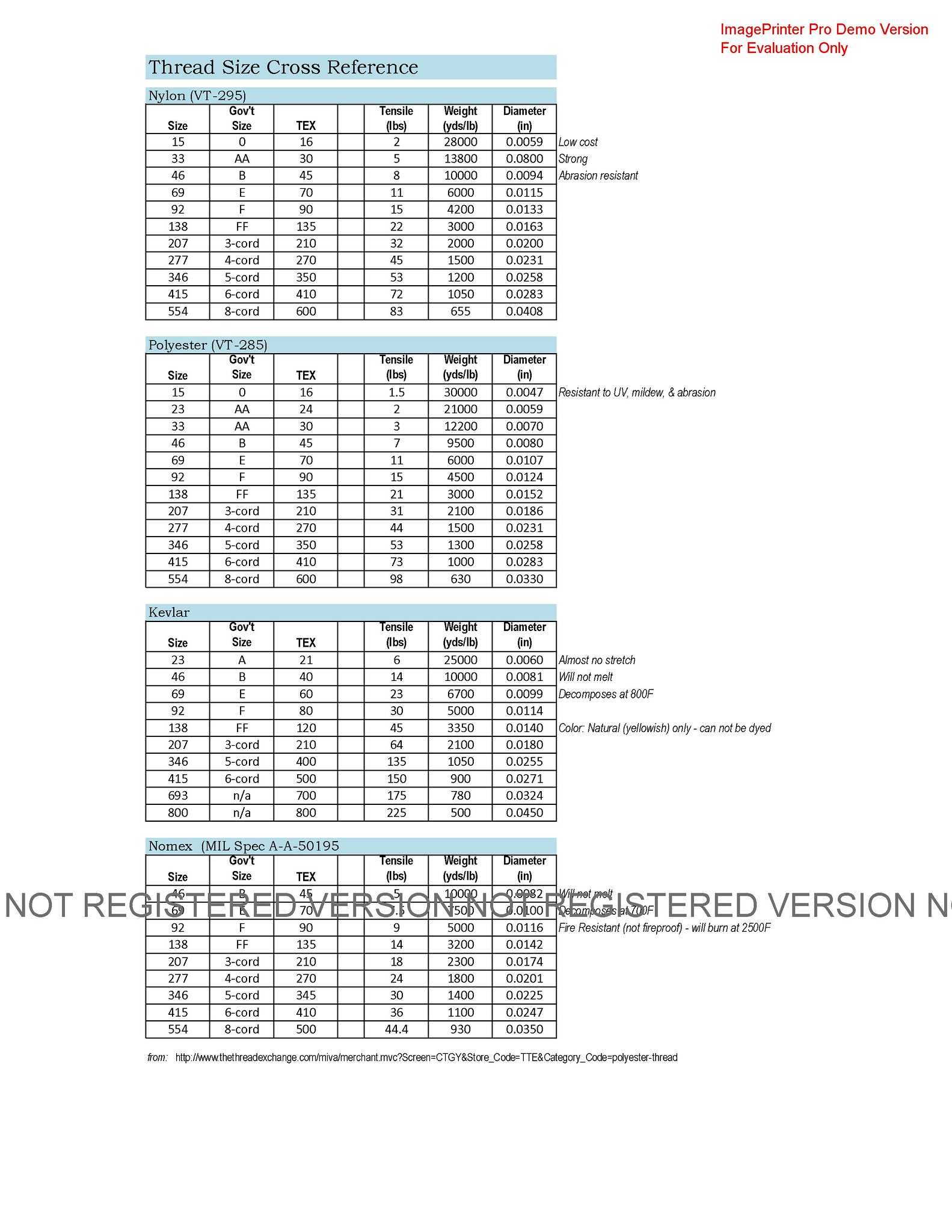

So far making some more gear straps it is doing pretty well, size 16 needle and v69 thread

View attachment 25026View attachment 25027View attachment 25026View attachment 25027View attachment 25027View attachment 25028View attachment 25028

Sent from my SM-G973U using Tapatalk