I had a gear go on a Singer 640. I was sewing and then nothing. I ordered the upper gear set and it took about an hour to replace. It was just inconvenient having it break and waiting for the gears.Some of those later metal machines have plastic gears, and they frequently strip, especially when sewing heavier materials. They are cheap, but time-consuming to replace.

You can remove the top cover to check the gears with usually just a screw or two (sometimes none).

-

The SH Membership has gone live. Only SH Members have access to post in the classifieds. All members can view the classifieds. Starting in 2020 only SH Members will be admitted to the annual hunting contest. Current members will need to follow these steps to upgrade: 1. Click on your username 2. Click on Account upgrades 3. Choose SH Member and purchase.

-

We've been working hard the past few weeks to come up with some big changes to our vendor policies to meet the changing needs of our community. Please see the new vendor rules here: Vendor Access Area Rules

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sewing Resources and Information

- Thread starter skell

- Start date

-

- Tags

- sewing thread thread injecting

I had a gear go on a Singer 640. I was sewing and then nothing. I ordered the upper gear set and it took about an hour to replace. It was just inconvenient having it break and waiting for the gears.

I've got young kids so 1 precious hour of project time = time-consuming!

I routed my industrial sewing machine top to fit modern hinges. They can be seen at the back in this video. I broke the only needle I had for this machine the other night and took the needle out of my other 281-1 to replace it. The shank is too big on the 281-1 needle. I used a needle that fit my 95-40 and it was shorter so I lowered the needle bar and proceeded to sew with a size 20 needle and V135 polyester thread. It worked better than I thought it would.

I cleaned up this old Singer 15 I picked up a few months ago. This was made in 1920 so it is 100 years old.

It worked OK with Tex40 thread with no tension problems. I will try it with some V92 thread soon. Here are two short videos for now.

These Singer 15 machines just work well with no problems, IMHO.

It worked OK with Tex40 thread with no tension problems. I will try it with some V92 thread soon. Here are two short videos for now.

These Singer 15 machines just work well with no problems, IMHO.

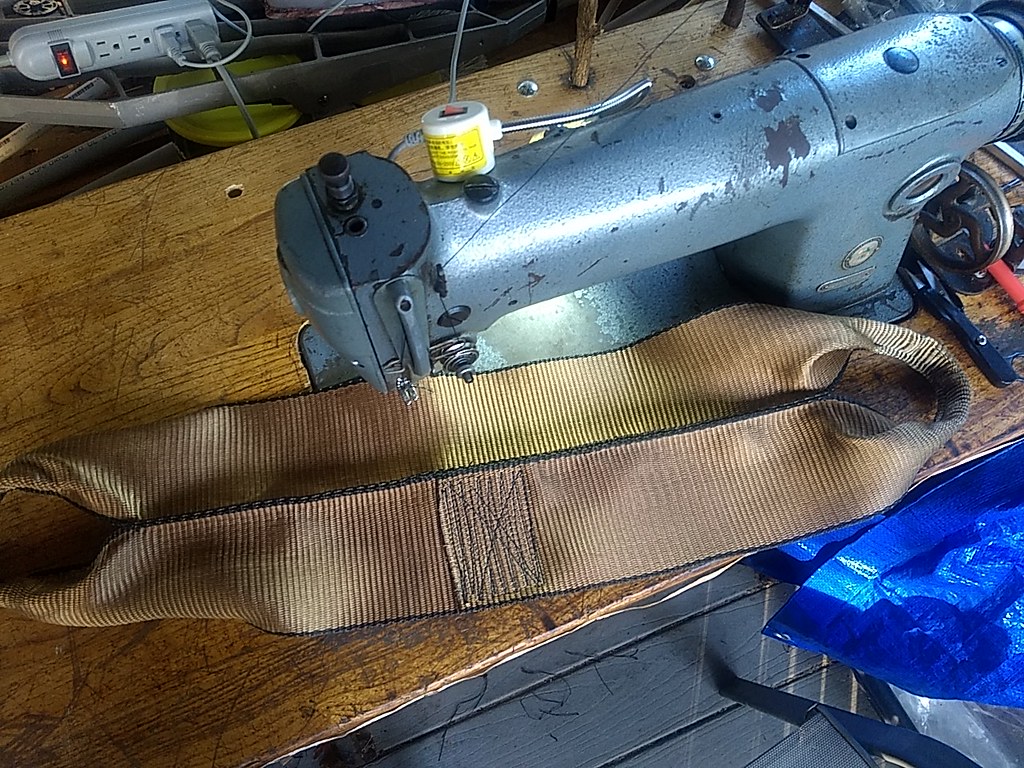

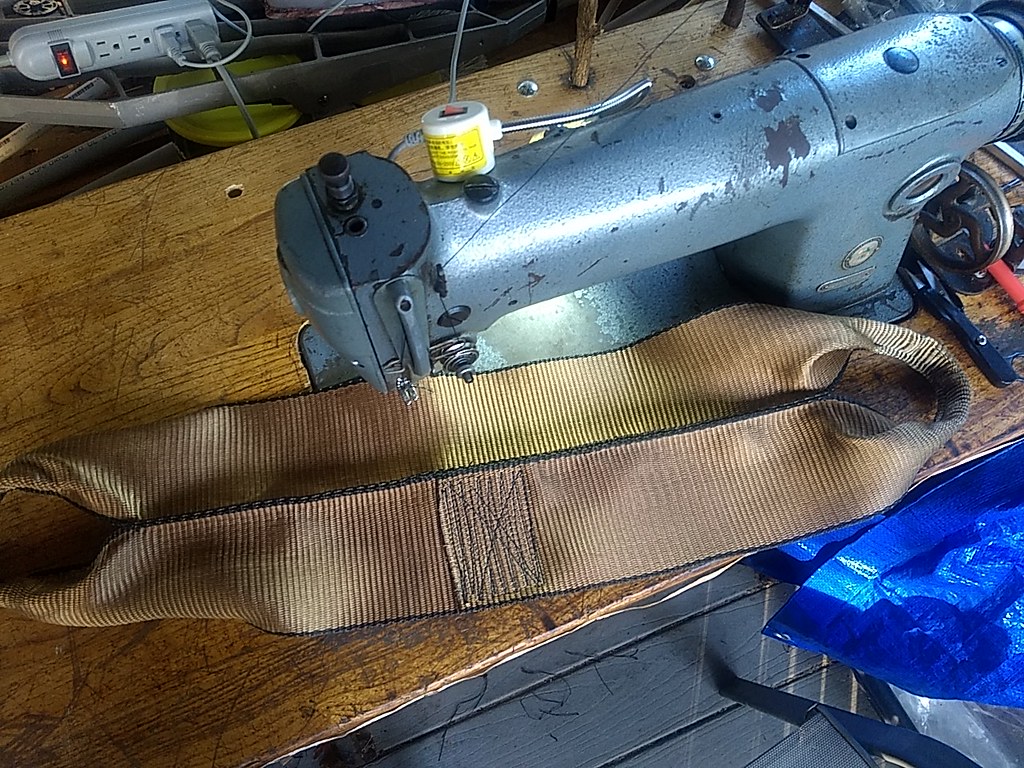

I started sewing another Yellow Jacket Saddle (tm) although this one has been dyed brown so maybe I should call the Brown Bear Saddle (tm). I used a Singer 281-1 sewing with V135 polyester thread with a size 18 needle. I need a size 20 needle or larger. I thought I bought some size 20's but I think I had trouble finding them so maybe not. I had trouble sewing 4 layers of this strap with this machine on the bridge loops but was able to do it by loosening the presser bar and presetting it higher. It will not sew thin material now but I can reset it if I need to. It takes about a minute.

Edit: I found the size 22 needles I bought before. Schmetz numbers are the same on the 18s and 22s but all the other manufacturers numbers are different so I couldn't match them up. Confusing.

Edit: I found the size 22 needles I bought before. Schmetz numbers are the same on the 18s and 22s but all the other manufacturers numbers are different so I couldn't match them up. Confusing.

Last edited:

Look out, world! Gonna be some parallel stitches coming your way.

I finally got around to (mostly) finishing what has been a couple month project I've been pecking away at every now and then... Prepping and routing a table top for my Singer 112W140, cleaning the machine up a bit, replacing the hooks, timing, and installing a servo motor. I still need to install a needle positioner, but who knows when I'll get around to that.

I finally got around to (mostly) finishing what has been a couple month project I've been pecking away at every now and then... Prepping and routing a table top for my Singer 112W140, cleaning the machine up a bit, replacing the hooks, timing, and installing a servo motor. I still need to install a needle positioner, but who knows when I'll get around to that.

Last edited:

A concrete mixing pan works great for temporary storage of an oily sewing machine. I put a plastic bag over the machine to reduce dust accumulation.

kenn1320

Well-Known Member

- Joined

- Sep 15, 2015

- Messages

- 2,753

Birdsnest under material? I set tension and can sew single pass fine. If I sew 2 webbing together the top looks great, but the bottom looks like 5x the thread. Doesn't get caught in the machine or anything. I don't even know its happened till I flip it to trim it. Google hasn't been any help as this Doesn't appear to be the normal type of birds nest issue.

Birdsnest under material? I set tension and can sew single pass fine. If I sew 2 webbing together the top looks great, but the bottom looks like 5x the thread. Doesn't get caught in the machine or anything. I don't even know its happened till I flip it to trim it. Google hasn't been any help as this Doesn't appear to be the normal type of birds nest issue.

Supposing you have balanced tension, sometimes this will happen if you need to use a larger needle.

kenn1320

Well-Known Member

- Joined

- Sep 15, 2015

- Messages

- 2,753

Think I fixed it. So machine had a problem missing half the stitches on max zigzag. I looked and could tell timing was off. Not knowing how to set it, I lowered the needle bar, which helped. Watching more videos, I learned about the 2 lines on the bar and what they are for. I set bar height and timing was way off. Being a mechanical guy, I figured out how to reset timing on a gear drive. Had to readjust tension and it even zigzags now.Supposing you have balanced tension, sometimes this will happen if you need to use a larger needle.

UPDATE: Just went back and added stitches to my saddle because the problem is resolved. I was even able to add bartacs with the zigzag feature. Hopefully this helps someone in the future.

Last edited:

Think I fixed it. So machine had a problem missing half the stitches on max zigzag. I looked and could tell timing was off. Not knowing how to set it, I lowered the needle bar, which helped. Watching more videos, I learned about the 2 lines on the bar and what they are for. I set bar height and timing was way off. Being a mechanical guy, I figured out how to reset timing on a gear drive. Had to readjust tension and it even zigzags now.

UPDATE: Just went back and added stitches to my saddle because the problem is resolved. I was even able to add bartacs with the zigzag feature. Hopefully this helps someone in the future.

Very impressed!

You may have to watch timing more on an industrial machine due to the nature of the sewing done on an industrial. I have only had to reset the timing for one of the 80+ machines I have had - but they were all home machines - and that machine had been dropped by a previous owner (needle bar bent).

John Thomas in NC

Think I fixed it. So machine had a problem missing half the stitches on max zigzag. I looked and could tell timing was off. Not knowing how to set it, I lowered the needle bar, which helped. Watching more videos, I learned about the 2 lines on the bar and what they are for. I set bar height and timing was way off. Being a mechanical guy, I figured out how to reset timing on a gear drive. Had to readjust tension and it even zigzags now.

UPDATE: Just went back and added stitches to my saddle because the problem is resolved. I was even able to add bartacs with the zigzag feature. Hopefully this helps someone in the future.

I'm glad you resolved it! Almost every 20U33 that has passed through my office came to me skipping stitches at max width. I'm guessing the extra wide stitch width makes the timing a bit more critical when compared to most other zig zag machines.

As you found out, tweaking the needle bar height is usually the easiest and most appropriate fix.

kenn1320

Well-Known Member

- Joined

- Sep 15, 2015

- Messages

- 2,753

The needle bar tweak was a bandaid. I put that back to spec and adjusted the timing. That totally changed the machines stitching.I'm glad you resolved it! Almost every 20U33 that has passed through my office came to me skipping stitches at max width. I'm guessing the extra wide stitch width makes the timing a bit more critical when compared to most other zig zag machines.

As you found out, tweaking the needle bar height is usually the easiest and most appropriate fix.

Somehow I overlooked the bit about timing still being off!The needle bar tweak was a bandaid. I put that back to spec and adjusted the timing. That totally changed the machines stitching.

Can a Speedy Sticher be used to stich two layers of nylon webbing together? If so what thread and needle would I use?

You definitely could use a Speedy Stitcher.

Needle size will be dependent on thread size, and thread size is dependent on the application. If you know what thread you want to use, I'm sure someone here (or at Speedy Stitcher) could help you out.

Thanks 4090Sharps, I'm thinking about trying to do some modifications on my original TreeSuit that I have. Was wondering what type of thread I should use.You definitely could use a Speedy Stitcher.

Needle size will be dependent on thread size, and thread size is dependent on the application. If you know what thread you want to use, I'm sure someone here (or at Speedy Stitcher) could help you out.

Thanks again,

Grits

I have one. I have sewed some canvas but no webbing. It doesn't seem as strong as a 15 class machine but it is very smooth. I bought this and a rusty Singer 66 for $40. The oscillating hook on a 15 seems to be particularly good at pulling tight thicker thread. The 201 had no cord but I had one plugged it in and oiled it and it worked fine. The 66 had the motor wire cut. I tried the 66 hand powered and it worked fine.

Edit: I may have sewed the ends of a piece of webbing together. I found this other picture.

Edit 2: I sewed this cushion cover with V69 thread with the 201 and top stitched the zipper section for strength.

Edit: I may have sewed the ends of a piece of webbing together. I found this other picture.

Edit 2: I sewed this cushion cover with V69 thread with the 201 and top stitched the zipper section for strength.

Last edited: