LeTuB

Member

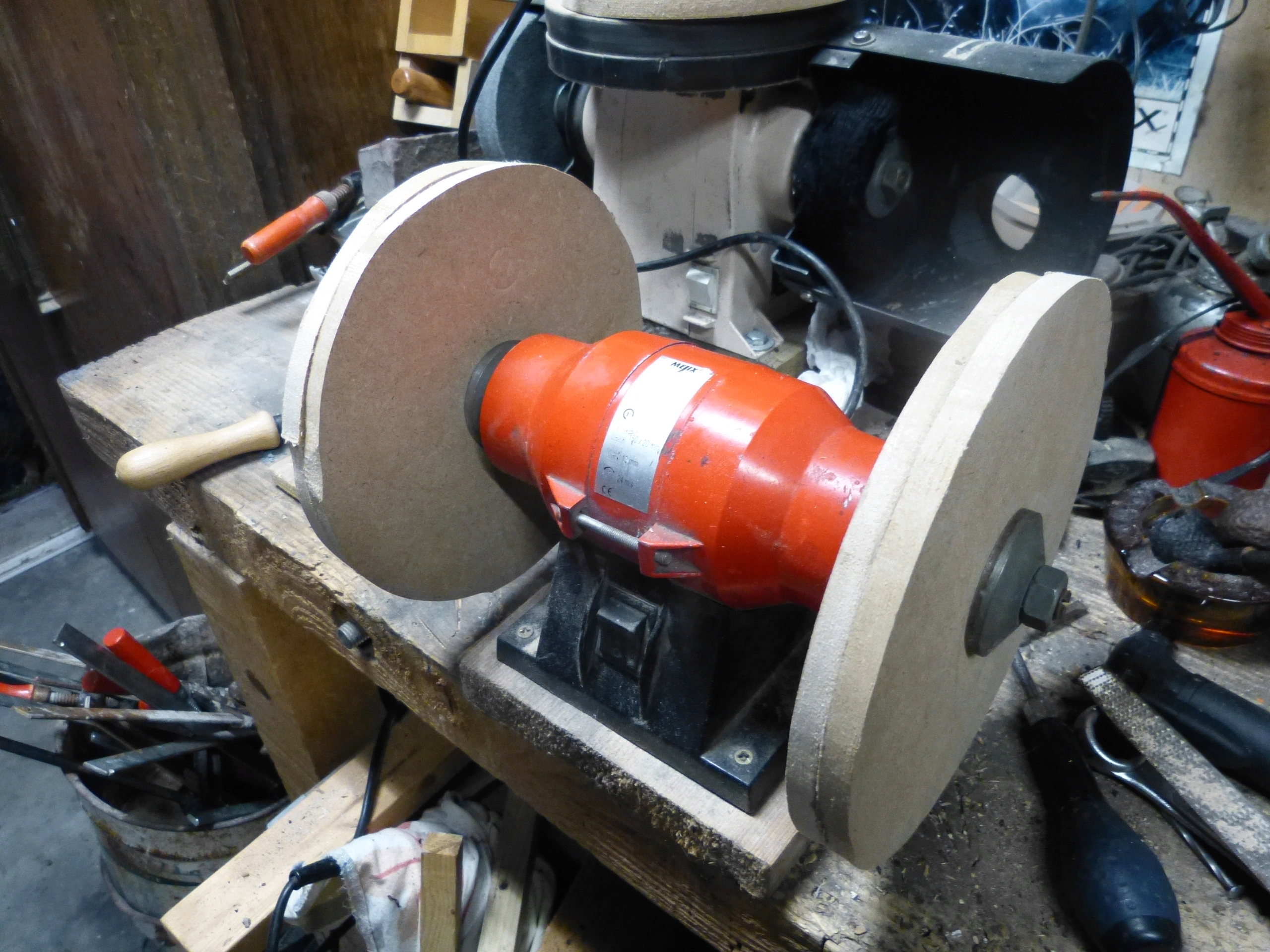

Roughly cut 8'' discs in a scrap 1/2'' MDF sheet.

Then glue by pair

Of course it's better if you have directly 1'' thick MDF

Drill center, then mount on the grinder

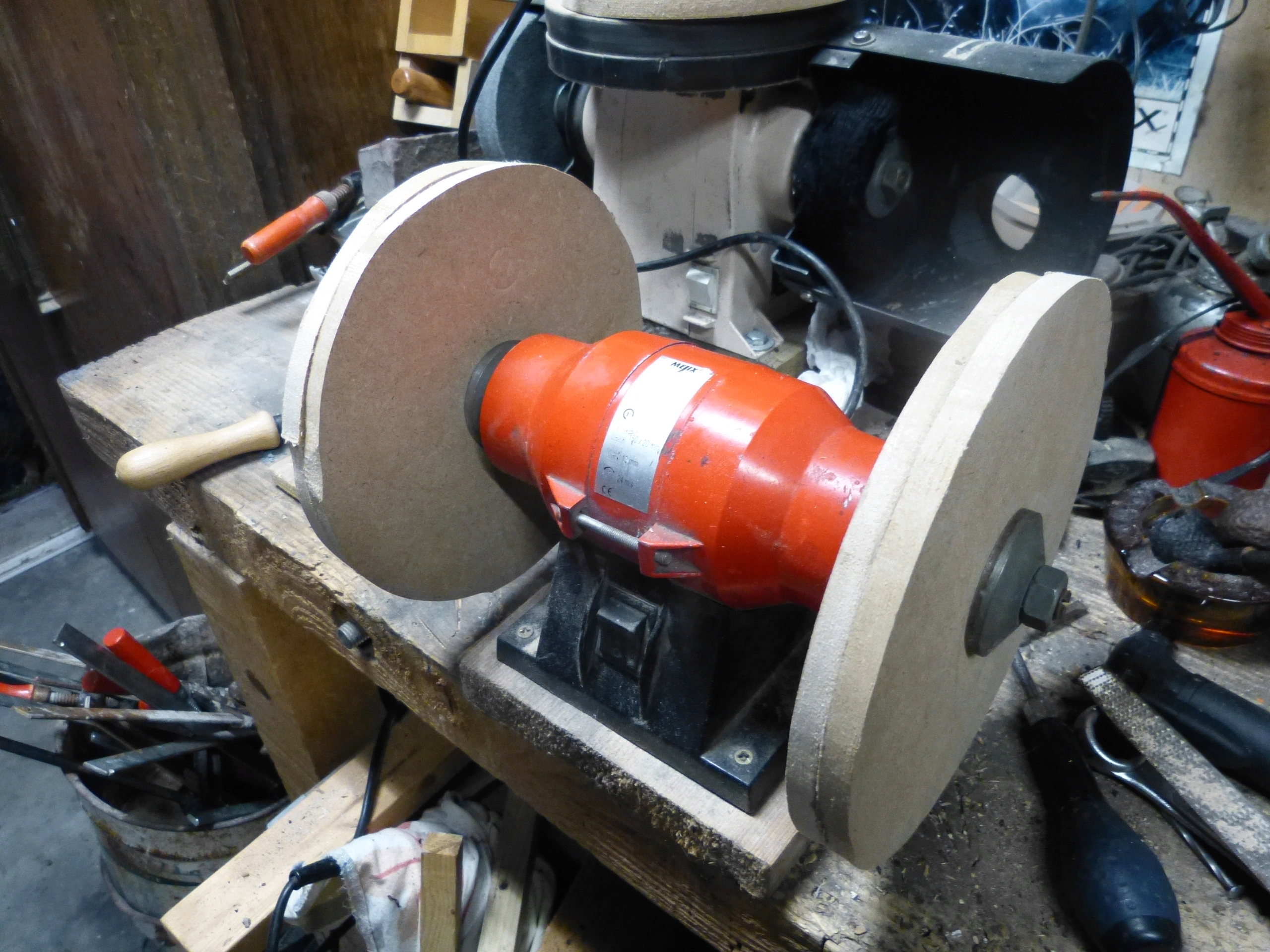

Give them the shape you want with a wood file and sandpaper (grinder ON) depending on what you want to sharpen

Here I rounded the edges for my concave BH

Then glue by pair

Of course it's better if you have directly 1'' thick MDF

Drill center, then mount on the grinder

Give them the shape you want with a wood file and sandpaper (grinder ON) depending on what you want to sharpen

Here I rounded the edges for my concave BH

Last edited: