So it turns out that I'm only okay-ish at hand sharpening two bladed broadheads. Good enough for government work on a knife blade but not good enough to make a broadhead scary sharp. I looked into the kme broadhead sharpeners but after scoffing at the price I figured that money would be better spent on other hunting gear.

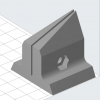

I modeled up a kme inspired sharpener for my 150 grain cutthroats and posted it on thingiverse: https://www.thingiverse.com/thing:4559963

I used a #10-24 x 3/4" machine screw and nut for the clamping force, but I think you could probably get away with a 1/2" screw. It's designed to be ambidextrous so right/left bevel shouldn't matter. My only concern is how the geometry changes between the different sized broadheads.

NOTE: when grinding your initial bevel, be sure to focus pressure on the leading edge of the broadhead and not the trailing edge of the sharpener. It turns out rough stones tend to eat away at PLA better than they do hardened steel, who knew?

I modeled up a kme inspired sharpener for my 150 grain cutthroats and posted it on thingiverse: https://www.thingiverse.com/thing:4559963

I used a #10-24 x 3/4" machine screw and nut for the clamping force, but I think you could probably get away with a 1/2" screw. It's designed to be ambidextrous so right/left bevel shouldn't matter. My only concern is how the geometry changes between the different sized broadheads.

NOTE: when grinding your initial bevel, be sure to focus pressure on the leading edge of the broadhead and not the trailing edge of the sharpener. It turns out rough stones tend to eat away at PLA better than they do hardened steel, who knew?