Since fall hunting seasons are winding down, and many are turning to offseason projects, I thought it wouldn't hurt to have a thread dedicated to sharing sewing machine attachments and tools that we've found handy in our gear making. Plus, we're pretty much all gear junkies here, so why not?!

To start it off, I just set up my Consew 332R (by way of @Western VA Hunter) with a couple swappable slide covers. I drilled and tapped each for binders I had on hand (3/4" straight and 1" right angle), set up each binder, and now can swap them out in just a couple seconds. The right angle binder is a little further from the presser foot than I would like, due to the length of foot and interference from the mounting bracket, but it gets the job done. It also has a wider throat to accommodate heavy materials and zippers, whereas the straight binder has a relatively narrow throat.

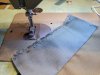

Example of 3/4" binding

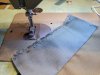

Over the summer I bought a large lot of sewing machine parts, and everyone now and then I'll find something new in the mix that I hadn't noticed before. This week I found this cool presser foot made to attach a 1/4" rolled hem to a second piece of fabric. The stitching is a bit close to the edge of the fabric, but I could see this specific foot being useful for connecting panels on a light jacket. A similar foot with the stitching moved inward would be great for joining pack panels.

I have a felled seam folder that I have yet to set up, but I'll share pictures of it later on. In the meantime, let's see what you're using on your machines!

To start it off, I just set up my Consew 332R (by way of @Western VA Hunter) with a couple swappable slide covers. I drilled and tapped each for binders I had on hand (3/4" straight and 1" right angle), set up each binder, and now can swap them out in just a couple seconds. The right angle binder is a little further from the presser foot than I would like, due to the length of foot and interference from the mounting bracket, but it gets the job done. It also has a wider throat to accommodate heavy materials and zippers, whereas the straight binder has a relatively narrow throat.

Example of 3/4" binding

Over the summer I bought a large lot of sewing machine parts, and everyone now and then I'll find something new in the mix that I hadn't noticed before. This week I found this cool presser foot made to attach a 1/4" rolled hem to a second piece of fabric. The stitching is a bit close to the edge of the fabric, but I could see this specific foot being useful for connecting panels on a light jacket. A similar foot with the stitching moved inward would be great for joining pack panels.

I have a felled seam folder that I have yet to set up, but I'll share pictures of it later on. In the meantime, let's see what you're using on your machines!