- Joined

- Jan 17, 2019

- Messages

- 6,283

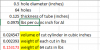

If your copying beast sticks the holes are every 1” OC, that gives you a 1/2” difference b/w the 2 planes….. if that makes any sense

so.....1/2" diam hole.....1" space.....1/2" diam hole.....and if you were to "unfold" the stick....then then spacing between holes on different sides would be 1/4" then?