With the discussions on sewing (or thread injecting if you prefer), I think it may be beneficial to those interested if we had a single resource thread for sewing information. I know a number of the little things I’ve picked up along the way are scattered throughout the forum. Please, if you have tips or resources which may be useful to those interested in sewing DIY gear, post them here!

Some helpful tidbits copy and pasted from other threads courtesy of @ckossuth:

- IMPORTANT!!!!!! You need to make sure the machine can handle a thicker industrial thread and that you can find needles to handle the thread as well. Remember, if you're making a saddle, THIS THING IS HOLDING YOUR ASS 20 - 30 FEET OFF OF THE GROUND!!! MAKE SURE YOU ARE USING GOOD QUALITY THREAD/MATERIALS AND YOU HAVE COMPLETE CONFIDENCE IN YOUR SKILLS!

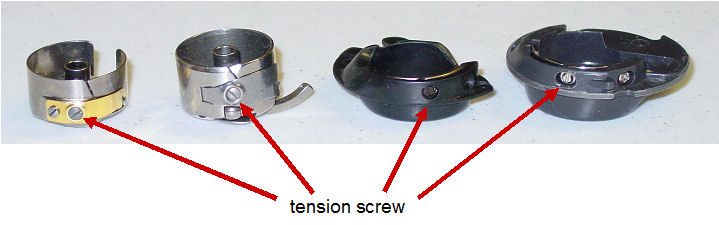

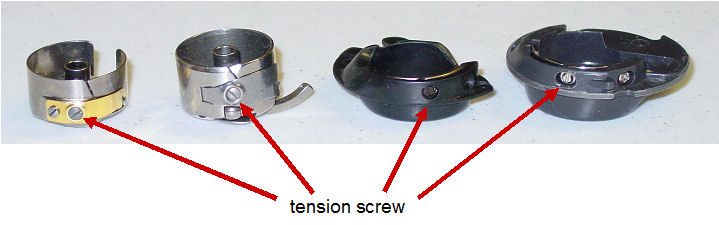

- Bobbin tension adjustment: Remember, we are not making dainty little dresses. We are making Man Gear! A seamstress will set their bobbin tension to where when holding the thread and letting the bobbin and cradle hang, it will very slowly start to fall. This is a good starting point (even for us). My personal preference (and this works on all 4 of my machines) is to tighten it to where when I'm holding the thread with the full bobbin in the cradle, I have to give the thread a little twitch to get the bobbin to start falling, and it only falls 6-8 inches before stopping again. Done. Set it and forget it. It's just one little screw. A little turn does go along way though.

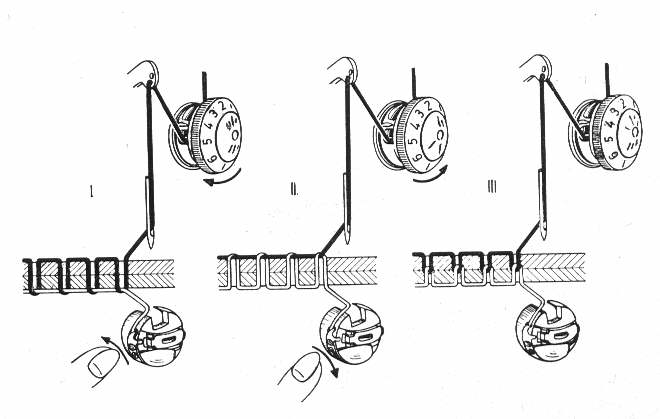

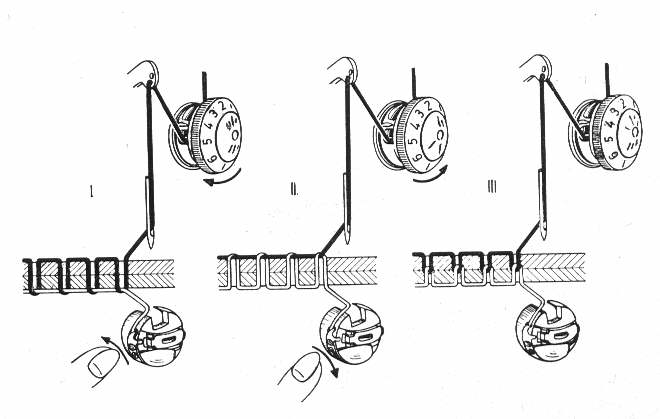

This person almost has it right. The thread should be going into the slot in the bobbin cradle and then up under the tension spring. This is to show how you should let the fully loaded bobbin and cradle hang when adjusting the tension.

Here is a great diagram.

Advice for buying a sewing machine

Advice for buying a sewing machine: find a decent used machine with metal gears (many machines from the 50’s and 60’s fit this bill). Another option...I know

@g2outdoors has had good luck with his newer singer heavy duty. I don't recall which model thread injector it is. I'm sure if you ask, he'd be glad to fill that piece in.

I am no sewing expert. And I will not pretend to have much for answers. But I do tend to go overkill on research.

----------------

For anyone searching/shopping for an older all metal sewing machine...

I stumbled across a great blog series on how to identify models of older Singer sewing machines from terrible online photos (which are standard on craigslist). If you decide on a particular model, this 5 part series is extremely helpful.

A Visual Guide to Identifying Singers from Crappy Craigslist Photos, Part 1

http://vssmb.blogspot.com/2011/07/visual-guide-to-identifying-singers.html

Helpful websites I have found:

www.thethreadexchange.com

- Information on thread and needles. Also has definitions for terminology which can be very useful. If you click on a category (needles, polyester thread, etc) there is an information are with “buying guides.” These are very helpful in decoding what means what.

www.diygearsupply.com

- The website has a section of DIY guides. There is a sewing tips page that shows different seams. There are also a number of patterns for outdoor gear that may help with planning your own project.

https://sewsweetness.com/2014/11/tutorial-shoulder-pad-straps.html

- Tutorial on how to make pads for bag straps. For example…the Wild Edge bag really needs one of these if you are going to carry it for any length of time by its strap.

https://www.schmetzneedles.com/learning/pdf/schmetz-needle-chart.pdf

- Posted by

@ckossuth in another thread. Good reference for type/size needle.

https://www.sailrite.com/How-to-Sew-Webbing-Loops (thanks

@Homebrew454)

- Great page on things to think about when wanting to sew webbing.

Books

On Rope. This book contains a great deal of information on ropes and knots. There is also a small section on sewing webbing and the differing strengths of stitch patterns.

Google search for the book:

HERE