-

The SH Membership has gone live. Only SH Members have access to post in the classifieds. All members can view the classifieds. Starting in 2020 only SH Members will be admitted to the annual hunting contest. Current members will need to follow these steps to upgrade: 1. Click on your username 2. Click on Account upgrades 3. Choose SH Member and purchase.

-

We've been working hard the past few weeks to come up with some big changes to our vendor policies to meet the changing needs of our community. Please see the new vendor rules here: Vendor Access Area Rules

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sewing Resources and Information

- Thread starter skell

- Start date

-

- Tags

- sewing thread thread injecting

- Joined

- Nov 1, 2018

- Messages

- 8,054

She thik

I bought this rusty beast for $12 on Ebay. It was worth about $12. It was close enough to me for local pickup. After oiling for a few days it was still very tight. I didn't think it would come back to life. After 2 weeks it is better. Sometimes the oil takes a long time to soak in. This is my first attempt at sewing with Tex40 thread. I still haven't cut the hole in my table bigger but it works. The servo motor works great. I don't know what the number is on the plate on the front. It doesn't seem like a model number. It looks to be Singer 281-1. The stitch length scale is lettered, not numbered.

Last edited:

I figured out why my $12 Industrial Singer was binding. The following videos tell all. @Weldabeast what would you recommend? Boat anchor?

Last edited:

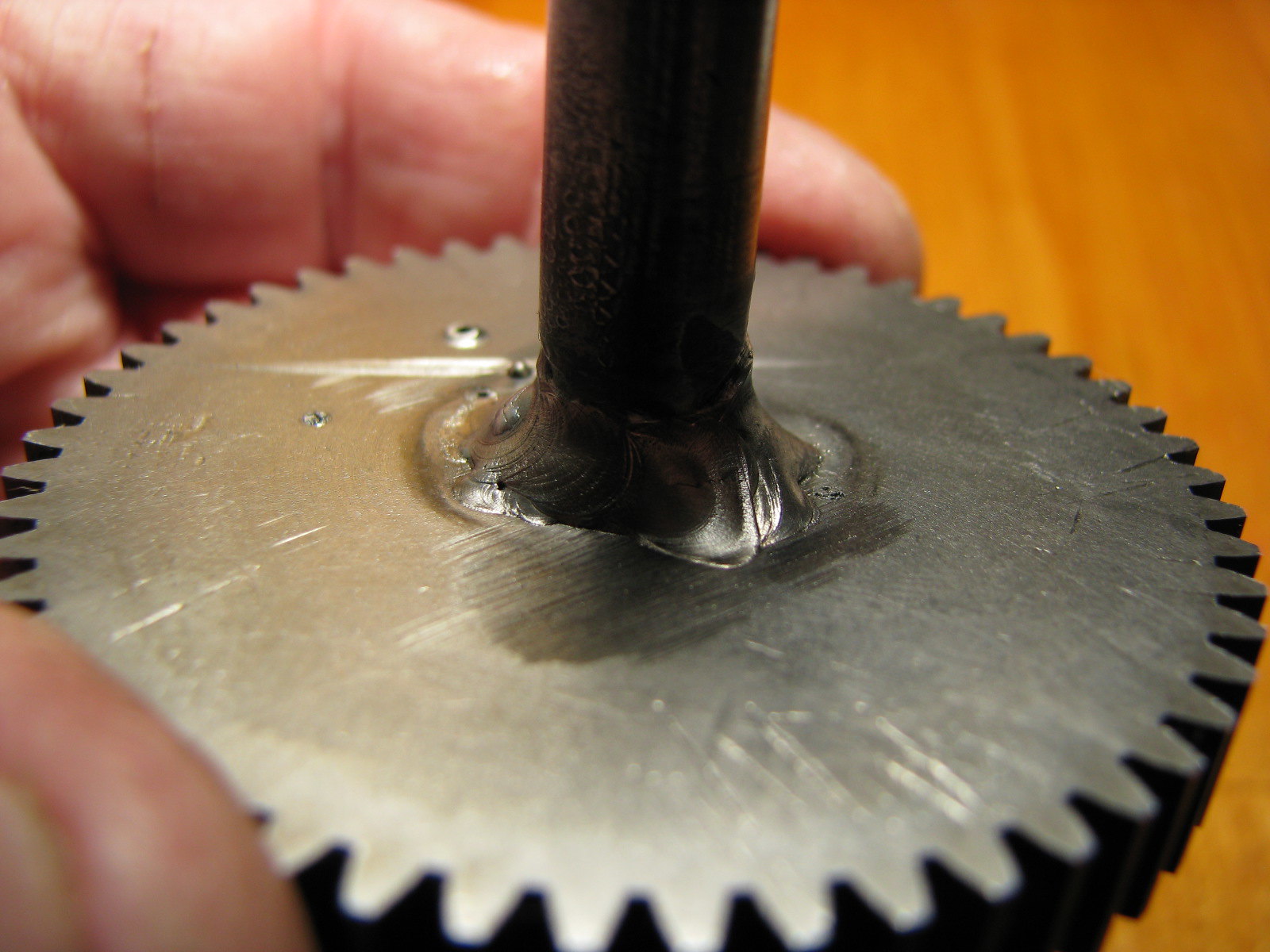

It can be repaired at any good fab shop....if it was me I would just figure a way to possible drill and tap some holes and bolt on some square tube or angle to straighten the deck out.....if u want to try to repair it you'll want to totally disassemble and remove all paint 1 or 2 inches surrounding the areas to be repaired. The crack will need a small hole drilled at the end of the crack and the crack ground out to a bevel. After welding peening is required and you'll want to wrap in leather or bury it in sand to allow a long cool down

The cool down is the most important part....the weld and base metal will need to cool at the same temp and same rate if at all possible

The cool down is the most important part....the weld and base metal will need to cool at the same temp and same rate if at all possible

Thanks. That sounds like a whole lot more than it's worth. If I ground a V and welded it what rod should I use? 6011?It can be repaired at any good fab shop....if it was me I would just figure a way to possible drill and tap some holes and bolt on some square tube or angle to straighten the deck out.....if u want to try to repair it you'll want to totally disassemble and remove all paint 1 or 2 inches surrounding the areas to be repaired. The crack will need a small hole drilled at the end of the crack and the crack ground out to a bevel. After welding peening is required and you'll want to wrap in leather or bury it in sand to allow a long cool down

The cool down is the most important part....the weld and base metal will need to cool at the same temp and same rate if at all possible

Edit: I think I'll try to screw on some angle iron like you suggest.

Last edited:

Thanks. That sounds like a whole lot more than it's worth. If I ground a V and welded it what rod should I use? 6011?

How to Weld Cast Iron

Learn about the steps required for successful in-house welding of cast iron parts.

That is a tuff repair for someone with limited experience....let a pro weld for u.

The thing I don't want to do is disassemble everything and I know that might destroy everything if I didn't.That is a tuff repair for someone with limited experience....let a pro weld for u.

If u were closer I'd help u

Bj139, quick ?, on my 15-91, I am having issues with the top thread bunching up underneath. I am not sure if it is the tension, or if something else is causing it. This is with v92, #18 needle, and a doubled up piece of 1” tubing. Trying to make my linesman loops. I was able to get one done, but on my second one, it keeps bunching up. I didn’t take pics, It seems to be looping up around bottom bobbin area. any thought? Lol

Tension. The thread is not being pulled up by the takeup lever. Your discs may be held open. Are you sewing with the presser foot up?Bj139, quick ?, on my 15-91, I am having issues with the top thread bunching up underneath. I am not sure if it is the tension, or if something else is causing it. This is with v92, #18 needle, and a doubled up piece of 1” tubing. Trying to make my linesman loops. I was able to get one done, but on my second one, it keeps bunching up. I didn’t take pics, It seems to be looping up around bottom bobbin area. any thought? Lol

I practiced on fabric and webbing for about a month before I attempted a saddle. It seems safer to have your Covid mask fall apart than to fall out of a tree.

Any weld process will work.....pre/post heat is the important part....u could try to run a tig bead with high nickel content filler rod but if that cast cools quicker than the weld it will crack again

Another weld process that seems to work good on cast iron is brazing..... I've never done it so you'd have to research

Tension. The thread is not being pulled up by the takeup lever. Your discs may be held open. Are you sewing with the presser foot up?

I practiced on fabric and webbing for about a month before I attempted a saddle. It seems safer to have your Covid mask fall apart than to fall out of a tree.

I’ll go recheck some tension stuff. Thanks

That's what I was thinking. I've brazed some steel in the past and it turned out nice. I'll think about it for a few days about the angle iron or brazing. Thanks.Another weld process that seems to work good on cast iron is brazing..... I've never done it so you'd have to research

Edit: I can fit some 1/4 inch flat steel between the frame and the round bar where it will be out of the way. Cracks are front and back as shown in the photo so I will have to add two bars. I have some bed frames which are high carbon steel for greater strength which I can cut. I will then drill and tap while bending the frame back with a wood block. Would it be better for me to use a thicker piece of low carbon steel like 1/4"?

Last edited:

If u are easily able to straighten by hand then any steel should be fine.....if possible drill a small hole where the crack ends.....that acts as a termination point and the crack shouldn't grow. I think some 1/4 x ? plate running down either side will fix u up....go the full length of the deck or as far as possible

Somebody dropped it at some point if I had to guess.

Somebody dropped it at some point if I had to guess.

I’ll go recheck some tension stuff. Thanks

Tension was part of it, I went up to a size 20 needle, the 18 was pulling the thread funny after I looked closer.

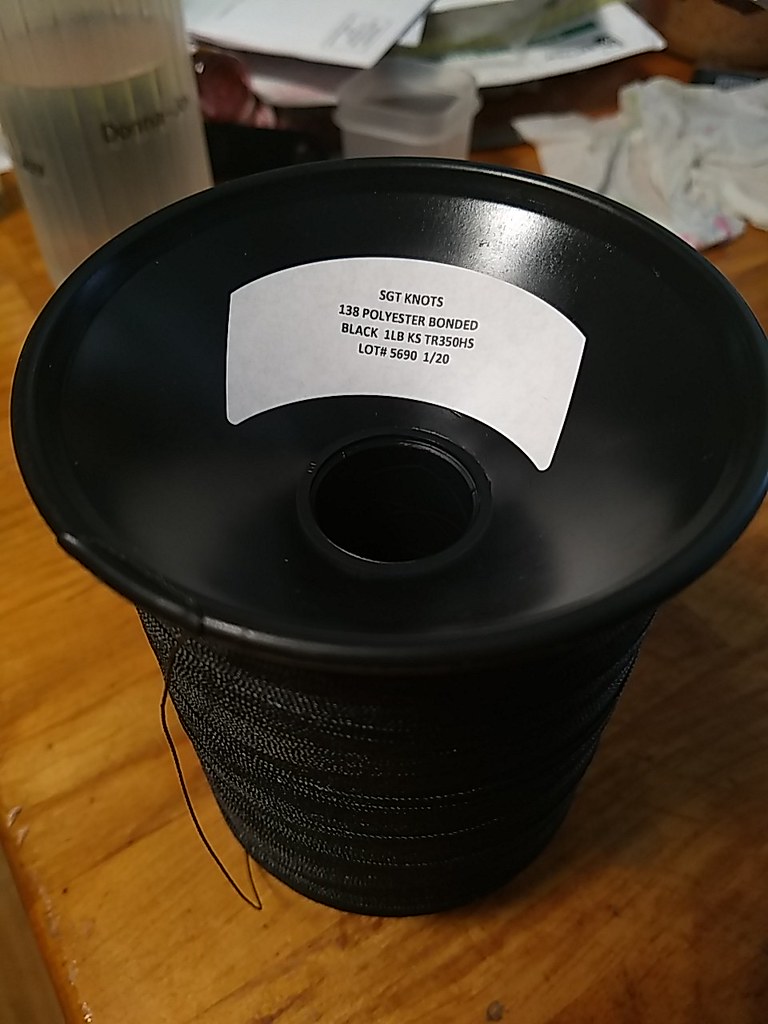

The thread should pass freely through the eye. The needle should slide up and down the thread when held taught with a needle on it. I posted a photo where a size 20 needle had about the same size eye as a 22 although the diameters were different as they should be. I guess manufacturers vary or maybe needle types vary. I bought some embroidery needles at Joanns labeled as having extra large eyes.Tension was part of it, I went up to a size 20 needle, the 18 was pulling the thread funny after I looked closer.