F1addict!

New Member

I have always had good luck with Schmidt needles.

Sent from my iPhone using Tapatalk Pro

Sent from my iPhone using Tapatalk Pro

Trying it is the only way to tell. Heavier machines are recommended for sewing webbing and other heavy material.This would be a new endeavor for me, but one that I think I could get in to and could be beneficial. This is what the wife has at home right now. Would this work for the majority of my needs in hunting related thread injecting?

I went with the Juki but the LSZ-1 was the other one I was seriously looking at getting. It would sew through what you need. They have a bunch of videos on the capabilities of that machine.Alright guys I need some input, here's my story.

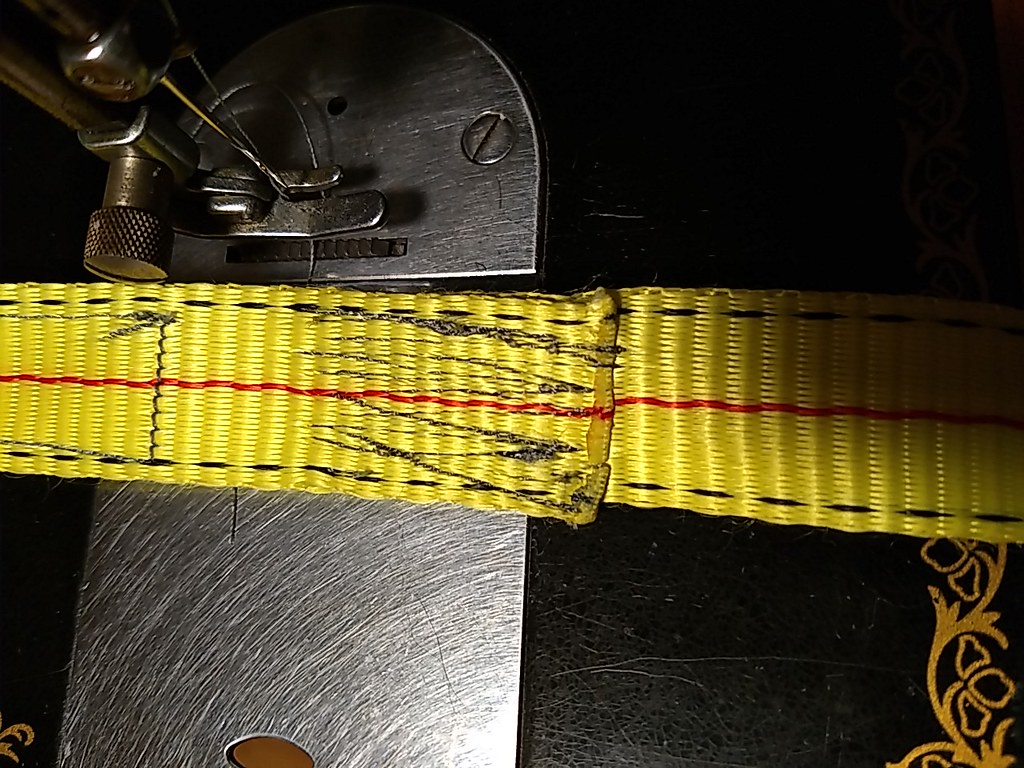

I've got a 15-91 that I refurbished and is in great shape that I want to use to make some diy saddles. It lays a beautiful stitch on multiple layers of cotton and denim items and most times with doubled up webbing. I say most times because on my practice pieces of webbing I found the machine would work fine laying a stitch in one direction but when I rotate the webbing 90 degrees to continue making a box pattern for example the needle would get stuck in the webbing while going in the new direction and I would have to use the manual flywheel with my right hand and help the needle out with my left hand to free it from the webbing. The underside bobbin thread doesn't lay as uniform and even as the top stitch either and sometimes the thread breaks, and yes I have tried different tension settings on both the bobbin and top stitch. I've been using singer needles from 16 to 20 with Gutermann tera 40 thread. The saddles I want to make will require going thru three layers of webbing and with my machine the stitching becomes noticeably more erratic and uneven to the point I will not attempt to produce a saddle with it.

So, my first question is have I reached the limits of the machines capabilities?

Now the next part...

I'm contemplating going deeper down this rabbit hole and buy a heavier duty machine. I know some love their Juki's while others have gone the industrial machine route but I don't want to spend $1300 plus to make a few saddles so industrial is not in my future unless I can pick up a used one at a discount. The Sailrite LSZ-1 seems like a great machine, walking foot and able to do a zigzag stitch for under $1k. The Juki 8700 is in the same price range but isn't a walking foot and unable to do a zigzag so I'm leaning towards the Sailrite because of the additional features and the portability. Does anyone own a Sailrite or have experience with one? More importantly, is there any doubt that the machine is capable of sewing three or four layers of webbing?

I'd love to hear input from the experienced thread injectors here on the pros and cons of any capable machine to meet my needs.

Another one you might consider is the Rex machine which is a clone of the Sailrite for around $450. You will need to apply a few fixes from what I have seen on the internet. Most people seem happy with it. I bought a Viking Husqvarna CL21A which needs repair on ebay. I am not sure if it will sew as is but I will post my experience with it here when I get it. It has a two speed gearbox for Sailrite type low speed sewing but no walking foot.Alright guys I need some input, here's my story.

I've got a 15-91 that I refurbished and is in great shape that I want to use to make some diy saddles. It lays a beautiful stitch on multiple layers of cotton and denim items and most times with doubled up webbing. I say most times because on my practice pieces of webbing I found the machine would work fine laying a stitch in one direction but when I rotate the webbing 90 degrees to continue making a box pattern for example the needle would get stuck in the webbing while going in the new direction and I would have to use the manual flywheel with my right hand and help the needle out with my left hand to free it from the webbing. The underside bobbin thread doesn't lay as uniform and even as the top stitch either and sometimes the thread breaks, and yes I have tried different tension settings on both the bobbin and top stitch. I've been using singer needles from 16 to 20 with Gutermann tera 40 thread. The saddles I want to make will require going thru three layers of webbing and with my machine the stitching becomes noticeably more erratic and uneven to the point I will not attempt to produce a saddle with it.

So, my first question is have I reached the limits of the machines capabilities?

Now the next part...

I'm contemplating going deeper down this rabbit hole and buy a heavier duty machine. I know some love their Juki's while others have gone the industrial machine route but I don't want to spend $1300 plus to make a few saddles so industrial is not in my future unless I can pick up a used one at a discount. The Sailrite LSZ-1 seems like a great machine, walking foot and able to do a zigzag stitch for under $1k. The Juki 8700 is in the same price range but isn't a walking foot and unable to do a zigzag so I'm leaning towards the Sailrite because of the additional features and the portability. Does anyone own a Sailrite or have experience with one? More importantly, is there any doubt that the machine is capable of sewing three or four layers of webbing?

I'd love to hear input from the experienced thread injectors here on the pros and cons of any capable machine to meet my needs.

Reading a bit more about the Juki 8700, I found that it is an industrial machine for light to medium fabrics not a machine for heavy fabrics. Juki has another machine with a walking foot for heavy fabrics.I found a couple different juki 8700h which is the one for heavier fabric around $7-800 range, but if you do a search on eBay for walking foot sewing machine you will find a bunch of used industrial walking doors for $4-1000 depending on what it is

There is a juki 8700s and juki 8700hReading a bit more about the Juki 8700, I found that it is an industrial machine for light to medium fabrics not a machine for heavy fabrics. Juki has another machine with a walking foot for heavy fabrics.

View attachment 24623

I was thinking if should I try to find a Juki but it runs in a oil bath. I only want to make a few saddles for me not go into production for sale. I don't need something too elaborate or expensive.There is a juki 8700s and juki 8700h

But in general I think a real walking foot machine is best for going over uneven materials and evenly feeding thicker materials

I have a portable walking foot machine coming from Canada but still look for a full size industrial walking foot. The juki 1181n and the consew 206rb have been the ones I have looked at mostly.

That’s one nice thing about the consew is that it doesn’t have a oil pan underneath but has oil ports on top that you oil every day you plan on sewingI was thinking if should I try to find a Juki but it runs in a oil bath. I only want to make a few saddles for me not go into production for sale. I don't need something too elaborate or expensive.