Will a bolt wallow aluminum faster than a roll pin wallow titanium?Doesn't that just show that the stainless grade you're using is more ductile than the aluminum one?

-

The SH Membership has gone live. Only SH Members have access to post in the classifieds. All members can view the classifieds. Starting in 2020 only SH Members will be admitted to the annual hunting contest. Current members will need to follow these steps to upgrade: 1. Click on your username 2. Click on Account upgrades 3. Choose SH Member and purchase.

-

We've been working hard the past few weeks to come up with some big changes to our vendor policies to meet the changing needs of our community. Please see the new vendor rules here: Vendor Access Area Rules

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

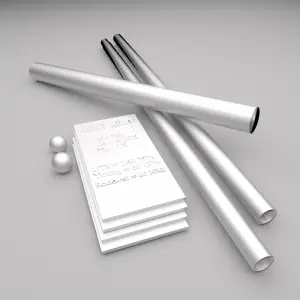

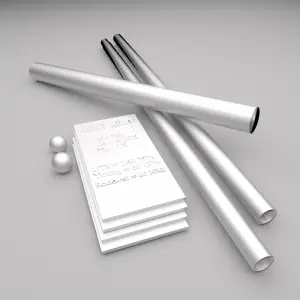

Tethrd One Climbing Sticks

- Thread starter rabidd099

- Start date

- Status

- Not open for further replies.

How long is a piece of string?Will a bolt wallow aluminum faster than a roll pin wallow titanium?

Depends on the type....How long is a piece of string?

My last thought before I depart.....roll pin is a press fit ....1/4 hole for 1/4 bolt....is there more play/slop with a roll pin or bolt? I'm out

To elaborate more, your stainless didn't break because it was ductile enough (and thin enough) to bend. The thicker aluminum was too strong and stiff to bend, so it split open. Thin aluminum, maybe annealed or with a WEAKER temper, would act more or less like the steel. Tearing apart like the aluminum did isn't necessarily related to wallowing - it just shows how much the material can stretch/bend.Will a bolt wallow aluminum faster than a roll pin wallow titanium?

I don't know the thickness of the tubing that tethrd uses, how snugly everything fits, etc. From looking at photos I can tell that you're not really getting any leverage on the pin to "wiggle" or bend it in the long direction - unlike a slightly loose bolt holding a step on - and the tube takes some of any bending load. (Like you mention) that slop matters a LOT, as does the leverage applied. So does the size of the hardware - a 3/16 pin in (say for example) 1/16 in titanium supporting the same load as a 1/4 in bolt through 1/8 in aluminum puts almost triple the stress on the hardware...

The tethrd design puts less stress on the components, but it uses thinner, lighter hardware, including structural adhesives that we already have reason to believe are not reliably applied. The design is a really good one! (I hope they are compensating @Sandor27) It also depends significantly more on high-quality and consistent manufacturing which is very much in question.

The real question is probably if the pins can loosen in the AL steps over time.

Aluminium Alloys vs Titanium Alloys - Comparison - Pros and Cons | Material Properties

Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. Titanium alloys have very high corrosion resistance and strength-to-density ratio, the highest of any metallic element.

material-properties.org

Yield Strength

Yield strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 240 MPa.

Yield strength of 2024 aluminium alloy depends greatly on the temper of the material, but it is about 300 MPa.

Yield strength of Ti-6Al-4V – Grade 5 titanium alloy is about 1100 MPa.

Yield strength of commercially pure titanium – Grade 2 is about 300 MPa.

So the 6061 aluminum would need to be 4.5 times as thick as Ti-6AL-4V titanium to have the same yield strength - the stress at which the material starts to plasticly deform.

Tethrd claims grade 9 Ti alloy (550MPa) So more in the neighborhood of twice as thick. But there are still many more factors involved...

Aluminium Alloys vs Titanium Alloys - Comparison - Pros and Cons | Material Properties

Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. Titanium alloys have very high corrosion resistance and strength-to-density ratio, the highest of any metallic element.material-properties.org

Yield Strength

Yield strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 240 MPa.

Yield strength of 2024 aluminium alloy depends greatly on the temper of the material, but it is about 300 MPa.

Yield strength of Ti-6Al-4V – Grade 5 titanium alloy is about 1100 MPa.

Yield strength of commercially pure titanium – Grade 2 is about 300 MPa.

So the 6061 aluminum would need to be 4.5 times as thick as Ti-6AL-4V titanium to have the same yield strength - the stress at which the material starts to plasticly deform.

- Joined

- Sep 13, 2018

- Messages

- 7,278

Tethrd claims grade 9 Ti alloy (550MPa) So more in the neighborhood of twice as thick. But there are still many more factors involved...

I didn’t measure but I think that tubing looked around 1/32” thick

The real question is probably if the pins can loosen in the AL steps over time.

This is sort of where I’m going with my line of questioning.

would love to get feedback from tethrd on how far down these types of paths they went. Or if they just pulled 900lbs a couple times in a uniform fashion and called it good.

smcchevy

Well-Known Member

would love to get feedback from tethrd on how far down these types of paths they went. Or if they just pulled 900lbs a couple times in a uniform fashion and called it good.

My dream job would be to 3rd party test (FEA, load test & certify, and then test to fail) every stick that is willingly send to me...

Might be time for an entrepreneurship endeavor...

Then again warm and fuzzy feelings don't pay the grocery bills.

- Joined

- Mar 21, 2018

- Messages

- 5,527

Nope....but they keep you from having to eat them through a straw.........

Then again warm and fuzzy feelings don't pay the grocery bills.

Last edited:

- Joined

- Sep 13, 2018

- Messages

- 7,278

I understand all of the continued concern of the roll pin/glue in this thread but just wondering if anyone has managed to break a stick to the point of failure yet? Or anyone willing to do their own at home torture test?

Glue failing.... yes

Roll pin failing....no

Glue failing.... yes

Roll pin failing....no

Obviously to this point I understand the glue fail, but is there any chance that the "roll pins will fail" camp could be wrong, and maybe they wont? I'm just looking for a total failure of stick before panicking and reselling them. Hoping I am not the first one it happens to, no offense...

smcchevy

Well-Known Member

Usually math keeps me personally from eating through a straw, but calculate darn near everything twice (once for the risk, and second since I'm from Kentucky).Nope....but they keep you from having to eat them through a straw....

- Joined

- Sep 13, 2018

- Messages

- 7,278

Obviously to this point I understand the glue fail, but is there any chance that the "roll pins will fail" camp could be wrong, and maybe they wont? I'm just looking for a total failure of stick before panicking and reselling them. Hoping I am not the first one it happens to, no offense...

The roll pin wasn’t designed to be the primary method of support for the step. I would be concerned since they only warranty the sticks for a year. Once that year is over you are on your own.

d_rek

Well-Known Member

The roll pin wasn’t designed to be the primary method of support for the step. I would be concerned since they only warranty the sticks for a year. Once that year is over you are on your own.

Does anyone else warranty their climbing sticks for a period of longer than a year? Genuinely curious. I googled and 1 year factory warranty seems pretty standard from all the other big brands (hawk, XOP, etc.) LWCG has lifetime on all nonwearable parts, but gives no date (at least on website) for the warranty on wearable parts. Beast gear has no warranty that I can see period.

- Joined

- Sep 13, 2018

- Messages

- 7,278

Does anyone else warranty their climbing sticks for a period of longer than a year? Genuinely curious. I googled and 1 year factory warranty seems pretty standard from all the other big brands (hawk, XOP, etc.) LWCG has lifetime on all nonwearable parts, but gives no date (at least on website) for the warranty. Beast gear has no warranty that I can see period.

Beast has a lifetime warranty, timber ninja has a 3 year warranty

d_rek

Well-Known Member

Beast has a lifetime warranty, timber ninja has a 3 year warranty

Interesting. Warranty is usually one of the last things I worry about when purchasing, which I should probably elevate higher on my priority list when making a purchasing decision.

That being said what would you feel would be a reasonable warranty period for the One Sticks? Or any stick for that matter?

paul.daniel.stanley

Member

- Joined

- Jun 6, 2020

- Messages

- 50

If Tethrd was smart (and I'm not claiming they're not), they would:

- build prototype sticks very similar to their competitors with the same grade aluminum/carbon fiber and bolts as the real thing

- go to a testing facility

- bring the "competitor sticks" and a Tethrd One stick

- go through each competitor stick and describe exactly how it is constructed and with what grade bolt and materials

- test each of those sticks to failure on video

- test the Tethrd One stick to failure on video

- post the video on YouTube

- watch their pocketbooks expand as fears about the Tethrd One dissipate and people are suddenly willing to shell out their hard-earned cash.

Just my humble recommendation. Take it or leave it.

Sent from my SM-N976U using Tapatalk

- build prototype sticks very similar to their competitors with the same grade aluminum/carbon fiber and bolts as the real thing

- go to a testing facility

- bring the "competitor sticks" and a Tethrd One stick

- go through each competitor stick and describe exactly how it is constructed and with what grade bolt and materials

- test each of those sticks to failure on video

- test the Tethrd One stick to failure on video

- post the video on YouTube

- watch their pocketbooks expand as fears about the Tethrd One dissipate and people are suddenly willing to shell out their hard-earned cash.

Just my humble recommendation. Take it or leave it.

Sent from my SM-N976U using Tapatalk

- Status

- Not open for further replies.