I recently bought a K1 MAX. For me, this thing is

fast. I have two other printers... I bought an Ender 3 back in 2019 on a flash sale for $110 and was plenty pleased with it. After a week or so I realized that

I had not printed anything since my kids kept it busy printing flexi dinosaurs and Pokemon stuff. I came across another flash sale on an Ender 3 Pro for around $120 and ordered that one. I made mods as time went on and needs increased. The Ender 3 is moderately modified (better hotend, BLTouch auto bed levelling, SKR board, RPi with Octoprint, better part cooling) and was the one for the kids. The Ender 3 Pro is heavily modified with the same mods as the Ender 3, plus linear rails, upgraded to 400x400 build plate, dual Z motors and increased height (350mm?), AC plate heater, etc.

The K1 MAX was pretty much ready out of the box. Here's a video of it printing a test file that came pre-loaded:

photos.app.goo.gl

If you look at the build plate, this is it's first print. It took about 15 minutes to assemble, and 10 mins or so to calibrate. Calibration is simple - select calibrate from the menu and it does the process unattended. I've been very happy with it so far, and it cuts my print times at least in half.

It is a little pricey IMO, and does have a couple of flaws.

Anyway - hope you don't mind

@7mmremmag , but I put a file out there to be able to mount a laser pointer to a camera mount such as yours:

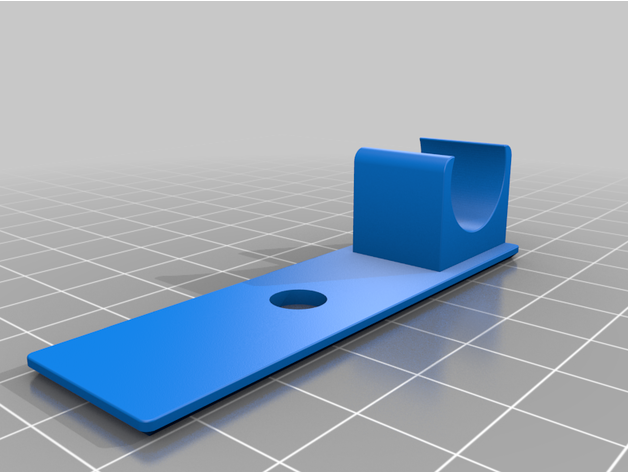

This is an adapter plate which sits on top of a 1/4-20 camera mount (such as a ballhead) and allows a cheap laser pointer (16.2mm in diameter, plus or minus) to be temporarily mounted to the bottom of the trailcam. This allows you to use the laser pointer to roughly aim where the trailcam is...

www.thingiverse.com

View attachment 98982

Since I put my cameras 8-12 feet up in trees while standing on a stick to deter theft, this lets me aim the camera using the laser pointer instead of guessing where it's aimed at. Clip the laser in, strap the camera up and aim with the red dot, and then unclip the laser pointer and climb back down.